How Main Battle Tank Software Works

Why software now drives the steel

Modern armour wins with codes as well as calibre. Main Battle Tank software synchronises sensors, weapons, mobility, and communications so crews can find, fix, and finish faster.

Moreover, it keeps critical functions predictable under fire, which is why engineers design MBT stacks like safety-critical aircraft systems rather than consumer apps.

Core languages and toolchains

Because milliseconds matter, developers still lean on C and C++. These languages give direct hardware controls for gun stabilisation, sensor fusion, and drivetrain management.

Main battle tank software uses them to compute ballistic solutions, stabilise the turret, and stream high-rate data from thermal cameras and laser rangefinders.

Ada for safety-critical control

Ada appears wherever reliability is non-negotiable. Its strict typing and concurrency help prevent runtime surprises in fire control, navigation, and interlocks.

Consequently, many Western defense programs still specify Ada in their highest integrity modules of main battle tank software.

Python, MATLAB, and Simulink for brains and models

Engineers use Python, MATLAB, and Simulink to prototype and test algorithms. Teams train Automatic Target Recognition (ATR) models, validate sensor fusion, and run hardware-in-the-loop trials.

They then auto-generate or hand-port proven control logic to C/C++ on the real-time targets. As a result, main battle tank software benefits from rapid iteration without sacrificing determinism.

Java and web tech for integration layers

Command-and-control middleware, GUIs, and diagnostic portals often run on Java or HTML5/JavaScript stacks. These layers handle map displays, health monitoring, and data exchange with external networks. Therefore, main battle tank software uses portable runtimes where strict real-time is not required.

Real-time operating systems and timing guarantees

An RTOS serves as the system’s metronome. VxWorks, QNX, or RTEMS schedule tasks so gun drives, inertial sensors, and stabilisers meet deadlines. With priority preemption and a fixed latency, crew members can traverse, range, and fire while manoeuvring. Without this foundation, Main Battle Tank software would stutter under load and miss shots that matter.

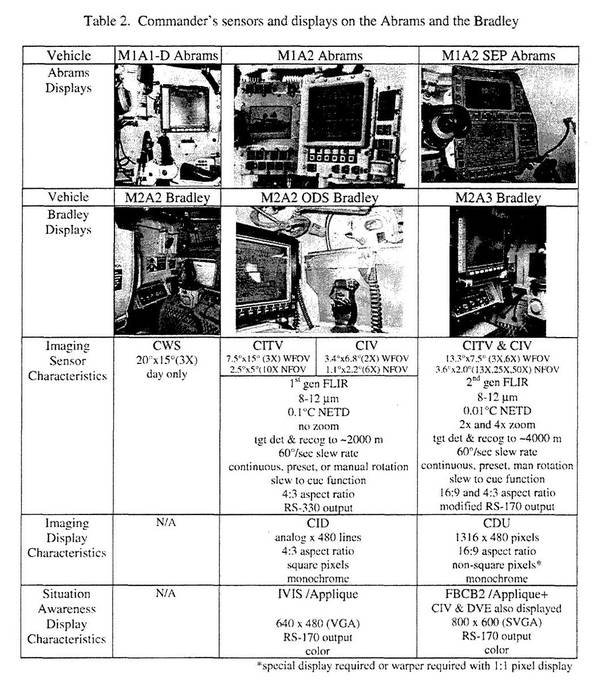

Fire control and targeting: compute, stabilise, engage

Modern FCS chains read range, wind, barrel wear, and vehicle motion, then produce a firing solution in real time. Gyro-stabilised drives keep the line of sight steady over rough terrain.

ATR aids in the detection and ranking of threats but keeps humans in the loop. Consequently, main battle tank software turns raw sensor feeds into stable reticles and first-round effects on target.

Sensor fusion pipeline

- Ingest thermal, daylight, laser, and radar channels.

- Time-align frames with the IMU and turret encoders.

- Fuse tracks to suppress clutter and reduce false alarms.

- Hand-off aim points to the fire control loop.

Mobility, drivetrain and survivability

The ECU and Transmission Control Unit coordinate torque, gear shifts, and braking for cross-country agility. Track tension and suspension modes adapt to terrain.

Health alerts show early signs of overheating or vibration. In practice, Main Battle Tank software balances speed, stealth, and mechanical sympathy to keep the formation moving.

Ammunition and weapon management

Smart loaders and store systems track round counts, types, and disposition. The FCS recommends the appropriate munition—APFSDS, HEAT, or programmable air-burst—based on target class and range. Therefore, main battle tank software reduces cognitive load, shortens the kill chain, and preserves scarce rounds.

Communications and networking

Secure radios and data links stitch tanks into the wider fight. SINCGARS provides robust voice/data in contested VHF. Link 16 is capable of sharing tracks and messages with joint military assets.

With encryption, anti-jam modes, and disciplined routing, Main Battle Tank software maintains connectivity even under electronic attack.

Battle Management System (BMS)

- Blue-force tracking and map overlays.

- Target hand-off to adjacent units and fires.

- Logistics cues for fuel and ammunition resupply.

- Command messages with acknowledgement and audit.

Crew interface and Human factors

Effective HMIs shorten decision time. Central displays merge platform status, threats, and navigation into one picture. Touch or button interfaces keep gloves in the fight.

Alerts escalate from soft cues to hard warnings as risk rises. Designed this way, Main Battle Tank software helps crews act faster without drowning in data.

Diagnostics, Maintenance and Lifecycle Support

Integrated Vehicle Health Management (IVHMS) records faults, trends wear, and suggests maintenance windows. Predictive analytics flag failing components before they halt operations.

Consequently, Main Battle Tank software cuts downtime and improves fleet readiness while reducing expensive breakdowns in theatre.

From model to metal: Development Flow

Teams sketch control logic in Simulink, validate it against recorded drives, then generate C for the RTOS target. At the same time, Python test harnesses are used to exercise edge cases and sensor anomalies.

After lab integration, hardware-in-the-loop rigs replicate turret inertia and engine dynamics. Finally, crews try out updates on ranges before fielding. This workflow keeps Main Battle Tank software auditable, testable, and mission-ready.

Security and Assurance

Defence programs harden codes with static analysis, memory safety checks, and a secure boot. They segregate networks between safety-critical and mission apps.

Moreover, digitally signed updates and tamper-evident logs protect the chain of custody. In short, Main Battle Tank’s software embeds cyber hygiene at the same level as armour and ERA.

What’s next: AI at the edge, responsibly

Edge AI will enhance ATR, route planning, and electronic-warfare cueing. Yet commanders will retain positive control of lethal functions.

With better processors and reliable machine learning runtimes, main battle tank software will provide smarter help while keeping things clear and allowing humans to stay in control.

References

- MathWorks—Model-Based Design with Simulink for Embedded Systems: https://www.mathworks.com/solutions/embedded-systems.html

- Wind River VxWorks RTOS (Defence and Aerospace): https://www.windriver.com/solutions/aerospace-defense

- NATO Link 16 Overview (Allied Data Links): https://www.nato.int/cps/en/natohq/topics_136547.htm

- U.S. Army—SINCGARS Tactical Radio (Field Manuals and Resources): https://armypubs.army.mil/